May 4, 2023

Supply Chain Due Diligence Technology: Which Tools Does Your Company Need?

The EU’s new anti-deforestation law, passed last week, is only the latest regulation requiring companies to perform due diligence on their extended supply chains. Enforcement for another supply chain law, Section 307 a.k.a. the US “Forced Labor Ban,” has resulted in more than 4,000 shipments being seized by US Customs since June 2022. What these laws have in common is a requirement to map and monitor the end-to-end supply chain, which many companies are ill-equipped to do because they lack visibility into their indirect suppliers, which often number in the tens of thousands.

A number of service providers have emerged to fill the gap, from supply chain mapping providers like Sourcemap to traceability technology like RFID and blockchain, watchlist providers, testing companies, and auditors specializing in sustainability. Which of these does your company need, and what’s the best way to deploy it?

Supply chain mapping software helps companies identify the stakeholders in their upstream supply chains. It’s an essential tool because traditional supply chain management (SCM) software wasn’t built to handle the volume of data needed to manage indirect suppliers, which are 5-10 times more numerous than direct suppliers. It's important to choose a proven solution that nimbly adapts and works across regions and raw materials. As new due diligence laws have increasingly broad mandates, companies will need to use the software to manage a continuously changing supply chain map.

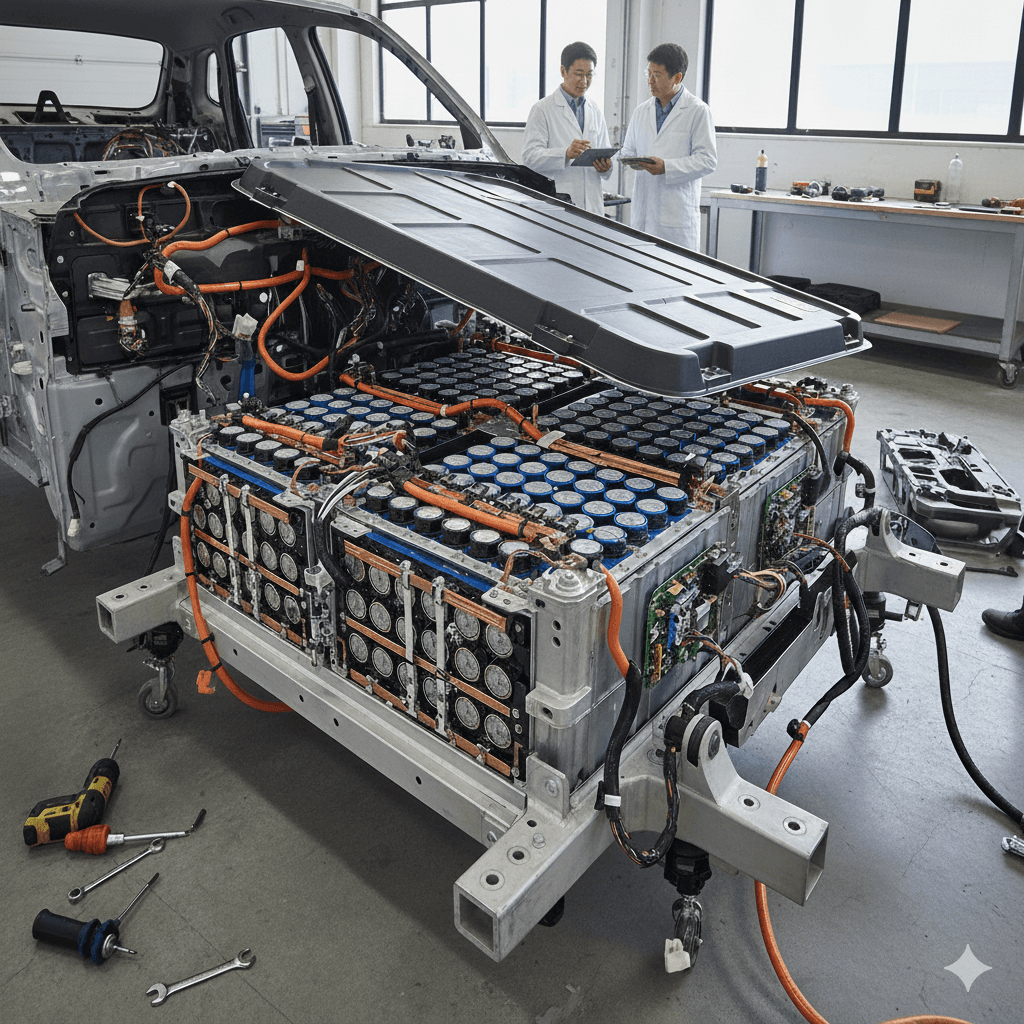

Traceability technology allows shipments to be tracked every step of the way, from the farms and mines where raw materials originate to the finished goods consumers buy. It ranges widely from traditional solutions like barcodes and RFID tags to emerging technology, such as digital twins and blockchain. Traceability technologies require new tooling, and as such are best applied to the most critical parts of a supply chain and often work best in industrial settings. For these reasons they’re typically limited to regulated applications. Regardless of which traceability technology is used, the underlying data needs to be uploadable to supply chain mapping databases to prove chains of custody. Within the supply chain mapping database, the underlying data is combined with similar data from vendors who do not use the same (or any) traceability technology.

Watchlist providers sift through vast datasets to provide companies with a way to quickly scan their suppliers for suspicious activity or affiliations. They range from traditional approaches, including market intelligence providers and research desks, to new approaches that rely on big data and artificial intelligence. Watchlists can save companies time by screening thousands of suppliers, especially as suppliers’ map their supply chains and discover more and more entities they do business with. It’s important to note that only your known suppliers can be flagged against a watchlist. The full benefit of a watchlist is only realized once you’ve mapped your entire supply chain, as you’ll then be able to look up many more of your suppliers for potential risks.

Material testing technology can be used to ascertain the geographic origin of some materials. The testing technology analyzes the isotope, chemical, and microbiome signatures that follow a material from origin to finished good. Testing technology is best used to confirm the results of supply chain mapping since only a finite sample of received goods can be tested. Further, testing technology only works for certain materials as some of the markers are corrupted by common manufacturing processes including smelting, refining, milling and dyeing.

Auditors remain the gold standard for verifying supplier practices onsite, and they’ve augmented their capabilities in recent years by compiling audit data through easy-to-use dashboards. High-risk suppliers flagged during due diligence ideally should receive an onsite audit, or, at minimum, have the documents submitted through supply chain mapping software to be reviewed by a remote or “desk” audit. Like testing, audits can only be conducted on a sample of suppliers, so it’s best to conduct audits with the regional and industry experts best suited to visit suppliers flagged during the mapping and watchlist process.

Will you need all of these solutions? Probably not. Every company with more than 200 direct suppliers will need supply chain mapping software because the due diligence laws all require additional visibility, whether it’s tier-1 and tier-2 visibility in the case of German Due Diligence, or visibility all the way to raw material suppliers as in the case of the US Forced Labor Ban. Watchlists also are widely applicable because they are a time-saving way to make sense of supply chain mapping data, and they don't require any investment by the suppliers. Traceability, testing and audits do require time and resources on the part of suppliers and should be carefully chosen based on the suitability for each industry, region and raw material.

Have more questions about the right suite of technologies for your supply chain due diligence? Email info@sourcemap.com. Our experts will assess your company’s exposure to supply chain due diligence laws and plot a path forward, including a road map to integrate the appropriate technology and services for timely compliance.